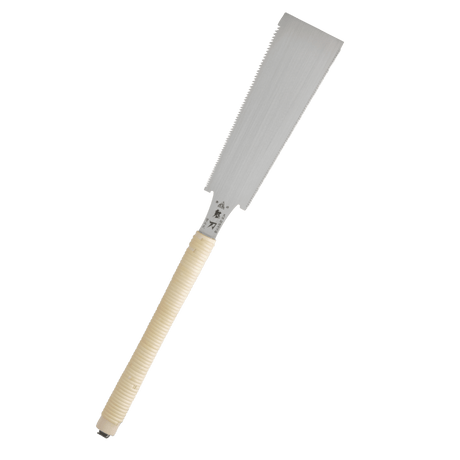

The Obvious

As with all Japanese saws, Ryoba saws cut on the pull stroke. This means that the blade is under tension as it cuts, and is pulled straight as it makes it's way through the work.

The Material

Whether soft or hard, wood's grain behaves very differently depending on it's orientation.

Cutting across the grain requires that the wood fibers be servered as if by a knife. Therefore, a good cross-cut blade has sharp opposing teeth that slice through the grain.

However, using such a blade to rip timber along it's grain is slow and difficult, as these teeth can't sever the tops of the fibers cleanly.

Instead, ripping down the grain is best achieved with a tooth profile similar to a row of small chisels. These teeth can cleanly cut down the timber fibres, and clear away the cut fibres quickly.

The Best of Both Worlds

Woodworkers will always need the flexibility to work the wood both across and along the grain, so what is one to do? Well, Japanese saw makers figured this one out some time at the start of the 20th Century.

Enter The Ryoba

The Ryoba carries a row of cross-cut teeth and a row of rip teeth on a single saw plate. This means that a single saw becomes capable of making most of the general cuts required when dimensioning timber.

Not only that, but notches, tenons and rebates can be cut with this single tool. Although fine objects and furniture will benefit from even finer saw plates (such as those found in dozuki style saws), if you are working on projects at a medium or larger scale, or on work that doesn't require perfect fit and finish such as shop fixtures, a ryoba is an excellent choice for the job.

Extended Life

As beautifully made as our saws are, no steel is impervious to wear, tear, and the ravages of time. If you are happy to have a go at sharpening your ryoba yourself, our Onikatana range is made from high quality Swedish steel, and has not been impulse hardened - and so can be resharpened with a fine file, good eyes and skill and patience.

However, our other Ryoba models have been impulse hardened. This means that the teeth are passed through an electrode that heats the metal white-hot before being allowed to cool. Such a heat treatment makes the teeth very tough, but unable to be sharpened.

All of our saw ranges, including the resharpenable Onikatana, offer replacement blades. These blades offer you a great way to keep your Ryoba saw cutting well for many years.

For the Gikoh ryoba, changing the saw blade only requires hinging open the latch. However, the rest of our Ryoba ranges can have their blades changed either by thumbscrew, screwdriver or allen key.